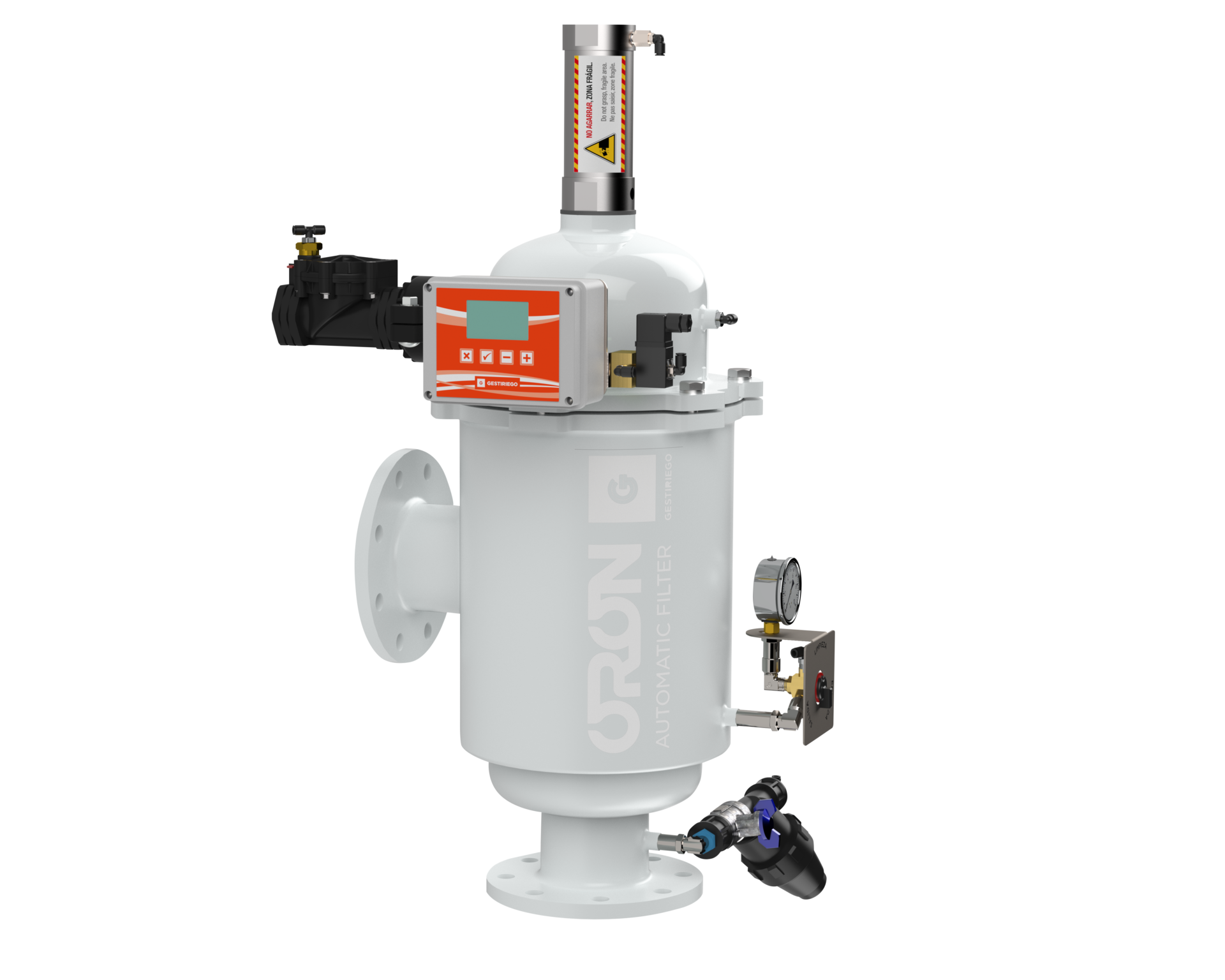

SELF-CLEANING AUTOMATIC MESH VERTICAL ORON FILTER

ORON IRRIGATION FILTERS

Thanks to their automatic cleaning equipment with a hydraulic system of suction nozzles, ORON filters do not need to interrupt the filtration phase for cleaning, so pressure losses in the system during the washing process are avoided.

Simpler equipment that gains in efficiency, specifically designed to meet the needs of the most demanding systems.

Departamento de I+D+i

Con más de 25 años de experiencia en el desarrollo de productos del sector.

Asesoramiento personalizado

Nuestro equipo técnico comercial resolverá sus dudas o necesidades.

Información técnica:

* En la versión móvil, deslice el dedo hacia la derecha para ver la tabla completa.

SELF-CLEANING AUTOMATIC MESH VERTICAL ORON FILTER | |||||

MODEL | CONNECTION | MAX. WORKING PRESSURE | MAX. FLOW RATE | FILTERING SURFACE | CODE |

(“) | (bar) | (m³/h) | Malla fina (cm²) | Filtro | |

ORV3” | 3" THREAD | 10 | 35 | 1200 | 461746 |

ORV4” | 4" FLANGE | 10 | 70 | 1800 | 461747 |

ORON FILTERS DESCRIPTION

Ideal equipment for systems with medium flow rates where professional filtration is required. The filters can work alone or in a bank (if the flow rates are very high or the water contains a large amount of dirt and requires an increased filtration surface). The filter is fully equipped, you just have to install the inlet, outlet and drainage connections, and assemble the other elements supplied according to specifications.

ORON FILTERS FILTERING PHASE

The dirt with a size greater than that established by the degree of filtration is retained on the inner surface of the mesh.

The filtered water exits the outlet of the filter in optimal conditions for its use, preventing damage from being caused to the system.

*Maximum operating pressure: 10 bar

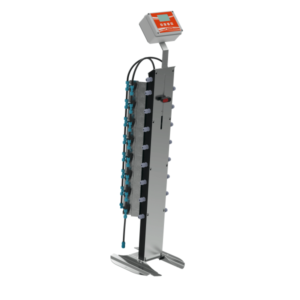

ORON FILTER AUTOMATIC SIMULTANEOUS CLEANING PHASE

From a pressure difference stipulated on the controller (recommended differential: 0.5 bar), the filter cleaning cycle starts automatically, which consists of activating a set of nozzles attached to a collector (washing unit) that siphon the dirt stuck to the surface of the mesh, expelling it to the outside.

In the cleaning process, a helical movement of the washing unit occurs, caused by the combination of rotational and translational movement, which results in a scanning of the mesh. Once the cleaning cycle is complete and the pressure differential has recovered, the filter is in the starting position and ready to perform another cycle.

*Important: Minimum pressure for cleaning: 2 bar