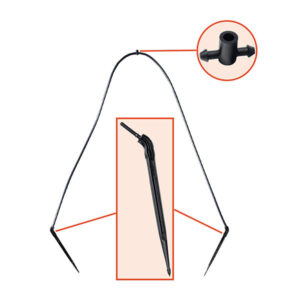

VP DOUBLE EFFECT AIR RELEASE VALVES

DOUBLE EFFECT VP IRRIGATION AIR RELEASE VALVES

VP AIR RELEASE VALVES protect your system from the dangerous air present inside it. They have the same incredible features as GTR air release valves except for their size, which is smaller and more compact.

GESTIRIEGO’S range of air release valves has its own patents, claiming exclusive advantages over its competitors.

Patent GESTIRIEGO P200502308 – Triple Function Valve for Hydraulic Systems-, through which a higher speed of extraction of residual air is achieved, due to the system of two buoys that act together, also guaranteeing a hermetic closure at low pressure.

With more than 25 years of experience in product development in the sector.

Personalised advice

Our technical sales team will solve your doubts or needs.

Technical information:

*In the mobile version, swipe to the right to view the entire table.

VP DOUBLE EFFECT AIR RELEASE VALVES | ||||

TYPE | SIZE | UNIT. BOX | BOX | CODE |

(“) | ||||

Double effect / VP-1 | 1 | 20 | V1 | 450530 |

Double effect / VP-2 | 2 | 12 | V2 | 450531 |

VP DOUBLE EFFECT AIR RELEASE VALVES CHARACTERISTICS/BENEFITS

√ WAVE SYSTEM CLOSURE Exclusive “wave system” closure patented by GESTIRIEGO. This guarantees the effective working of the air release valve, allowing the expulsion of high air flow rates when the system is under pressure and ensuring a low pressure closure.

√ A SINGLE AIR RELEASE VALVE HANDLES THE 3 OPERATING PHASES OF YOUR SYSTEM WITH A SUPER REDUCED SIZE Filling the system: the air is extracted efficiently since the float is kept away from the kinetic air outlet hole. When the water reaches the VP air release valve, the thrust of the float lifts the shutter, thus throttling the silicone pipe and closing the kinetic and automatic air outlet holes. In this situation, the air release valve is completely air tight from a pressure of 0.2 atm. Emptying the system: when the system is emptied, the float descends next to the shutter, causing the opening of the kinetic hole of the air release valve and allowing the air to be sucked from the outside, thereby preventing the pipes from being crushed. Operating under pressure: when the air pockets reach the air release valve, the float descends, deploying the silicone pipe, while the shutter closes the kinetic air outlet hole, allowing the air to automatically exit through the silicone pipe.

√ RESISTANT MATERIALS High resistance to pressure and chemical agents dissolved in irrigation water. Both the gasket and the pipe are made of silicone, much more resistant to these products than materials such as EPDM or NBR. In this way, the working of the air release valve can be guaranteed for a longer period than other similar products on the market.

VP DOUBLE EFFECT AIR RELEASE VALVE APPLICATIONS

•Suitable for applications in agriculture, because its materials are highly resistant to the chemicals used.

•Underground irrigation systems.

• Industrial systems: water treatment, osmosis, pumps, etc.